Equipment Screens

A RoofScreen® may be something added to a building to enhance aesthetics, or even make an architectural statement. Or, it could be a plain façade on the back of an old warehouse to satisfy city rooftop screening ordinances. No matter your project goal, we’d love to help.

Get A Quote

RoofScreen® Benefits

An equipment screen simply cannot leak. It’s just as important as the roof itself. Nobody wants leaks. Collateral damage, business disruption, liability, lawsuits and reputations are at stake.

An equipment screen is like a sail attached to your roof. Wind is a powerful force and the structural design of an equipment screen is nothing to take lightly. Don’t risk leaving that work up to someone with little or no experience.

Incredibly strong structures can be built with this simple bolt-together design. Adjustability is unlimited because of the way the fittings slide to the desired position and fasten with self-drilling tek screws.

Equipment Screens Designed With A Purpose

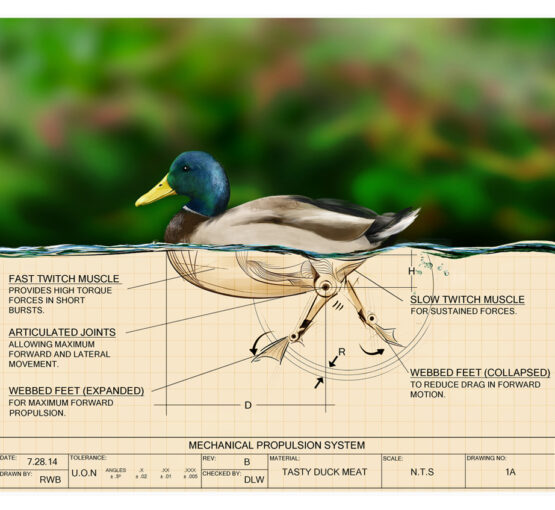

When you watch a duck moving across a pond, what you see is a beautiful, calm, colorful duck. What you don’t see is all the amazing mechanics happening below the waterline.

When you work with RoofScreen, you can focus on the nice stuff above the waterline (roof). We’ll take care of all the unseen technical mechanics.

Real engineering is highly dependent on specific site conditions. That’s why RoofScreen provides you with the full package, tailored to your specific project. Generic rubber stamped “engineering” data sheets just don’t cut it with us.

No animals were harmed in the making of this photoshopped image.

We're Different

How Much Does A RoofScreen® Cost

We hate to say it depends, but… it depends. If you are willing to call us, and we hope you are, we can provide quick, accurate quotes for fully engineered equipment screen systems. Otherwise, check out the list on the right to learn more about the different factors that can influence the price of rooftop screening.

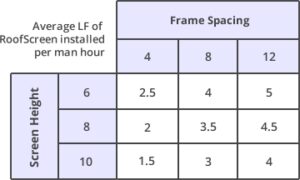

What is the labor cost?

Through testing and feedback from our customers over the years, we have formulated some guidelines for installation time. There are many factors that affect installation time like worker skill, jobsite access, screen parameters, etc. We can’t tell you how long it will take, but we can provide these helpful data points you can factor into your estimate:

There are multiple factors that play into this but all you really need to know is - the taller the frame, the more expensive the equipment screen.

Every inch in height of panel adds wind load to the screen wall. The higher the wind load on the equipment screen, the higher the cost. If you're trying to save money you may want to consider leaving a large gap at the bottom of the panel if line of sight allows.

One of the biggest cost factors is quantity of frames. The most cost effective option is to space the frames as far apart as engineering will allow. Frame spacing is greatly affected by wind load, frame height, panel height and locations of HVAC units.

Panel costs vary greatly and can have a big impact on overall project cost. To see a chart showing the cost difference between panels types, please see page 6 of our Design Guide.

Typically panels mounted horizontally are the most cost effective, except in cases where the frames are spaced farther than their spanning capabilities allow, typically about 8' to 10' O.C.

The simpler, the better. To keep costs down, stick to straight runs when possible and limit jogs, corners and access gates. If you have several RTU units to conceal it is usually better to do one single large RoofScreen rather than several small ones.

Steel Tube Framing for Bulletproof Builds

RoofScreen® tubing is stronger and more corrosion resistant than standard pipe. Our high strength mechanical tubing has been tested to last more than 4 times longer than typical schedule 40 pipe. Various sizes and gauges are available as well as additional services like end crimping and curving.

Roofing Attachments and Accessories

Square Base With RotoLock™

Designed to mount to various types of roof structures and adjust to the roof pitch with our ingenious RotoLock™ feature.

Learn MoreRound Post Support

Provides increased vertical flexibility because the Post Cap and Roof Flashing Boot are independent of each other.

Learn MoreSquare Post Support

Designed to attach to our LT™ Frame and other Light-Duty Framing systems utilizing a Square Post connection.

Learn More

Thermal Break

Thermal bridging is often a concern on commercial roofs. RoofScreen has a solution for this problem.

Learn More