People ask us all the time “what’s the cost of your RoofScreen system?” We wish pricing an equipment screen was that simple. Boy would our lives be easier if we could just say “Model A is this much, Model B is that much” and so on. But it just isn’t that easy. It’s kind of like calling a mechanic and asking “how much would it cost to fix my car?” He’s going to have to ask a lot of questions before he can give a meaningful answer.

We ask a lot of questions too. We’ll get into that in more detail below, but first let’s start at a higher level. You may simply be trying to figure out the general ballpark price so you can decide whether to invest the time to work through all the details. We get that and want to help. That’s why we give you a lot of pricing information in the “How Much Does A RoofScreen Cost” section of our website (about halfway down the page). You can also give us a call and we can throw out numbers on the phone based on as little information as you want to give us. But the title of this article is “How to Get the Best Price on a Roof Screen”. When we throw out numbers over the phone, they are just WAGs. In case you’re wondering what a WAG is, it’s an official construction term meaning “wild *ss guess”.

So to get the best price on a roof screen, you will need to get us more information. The more you can get us the more accurate the price will be. Notice we didn’t say “lowest” price? That’s because the best price might not necessarily mean the lowest price. The best price is an accurate price because if we estimate something on the low side, you’re not going to be too happy if you move forward with the project and the price ends up higher in the end. Conversely, if we throw out a price that’s too high, none of us win the job. That’s no good either.

So you’re on board with getting us more information? Great! That doesn’t necessarily even mean you have to spend more time. We are happy to do take-offs from plans if you have them. Go ahead and send us the PDF’s and we’ll sort through them and find what we need. In fact, we don’t even want you to try to extract only the pages in a plan set you think we need. We’ve found that we usually end up with missing information that way. Just send us the whole thing including the architectural, structural and mechanical plans.

That works great for new construction jobs or big retrofits when plans are available. But for projects that don’t have plans the process gets a bit harder. Below is a list of data points we need to provide accurate pricing. Ideally, we would like every one of them answered, but we also understand that may not always be possible. Just remember, the more information we have, the more accurate your pricing will be.

• Project address: This is needed for wind loading reasons. We will look up the address in the ASCE7 wind contour maps and determine the correct wind speed. We also look at satellite images to make sure we use the correct wind exposure factor based on the surrounding terrain. These are important items. A seemingly identical equipment screen in two different locations can have dramatically different prices based on wind loads alone.

• Occupancy use: How the building is being occupied also affects the wind load used for the design. It factors the wind loading depending on the importance of the occupancy, or risk factor to the occupants. For instance, fire stations, schools and hospital emergency rooms are factored higher than office buildings or warehouses. There’s a lot more to it than that, but we’ll figure that out. We just need you to tell us what the building is being used for.

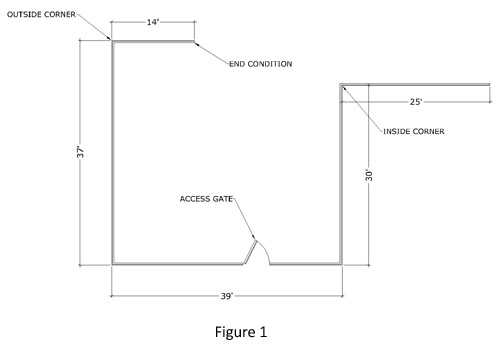

• Sketch of the roof screen layout: The actual layout of the screen can impact the pricing. Corners, jogs, etc. are all taken into account. For instance, a single 200ft long L-shaped screen with 1 corner would be a much different price than 8, 25ft long U-shaped screens, even though they are both 200ft of screen. If you don’t have a layout sketch, we would at least need the total lineal footage, number of outside corners, number of inside corners, number of end conditions and number of gates. For example, the screen in Figure 1 has 145 lineal feet, 3 outside corners, 1 inside corner, 2 end conditions and 1 gate.

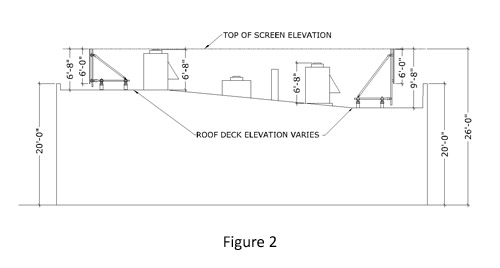

• Maximum elevation: This is the height in feet from the average level of adjoining ground to the top of the roof screen (see 26ft dimension in Figure 2). This is also a wind loading item. Wind loads are factored for elevation and increase with building height.

• Maximum screen height: This is the height of the actual equipment screen, not to be confused with the Maximum Elevation question described above. This dimension would be measured from the roof deck (below any rooftop insulation) to the top of the screen. We’re looking for the maximum screen height, so this should be measured at a location where the RoofScreen is at the lowest point in the roof slope. For example, in Figure 2, the maximum screen height is 9’-8”.

• Height of face panels: This is one of the biggest factors for pricing. That’s because the panels act as a large sail putting wind pressure on the equipment screen. The higher the wind load, the higher the price. So for every inch of panel height you can shave off, you are reducing the overall wind load and helping your price. Let’s say you have a roof screen similar to the one in Figure 2. The screen height on the right hand side is 9’-8”, but there’s no reason to make the panels that tall because they can’t be seen beyond the parapet wall. This greatly helps the loading on the frames, allowing them to be spacing farther apart, reducing material and labor costs. So the panels in this example are shown as 6’-0” which are tall enough to cover from the top of the parapet wall to the top of the screen.

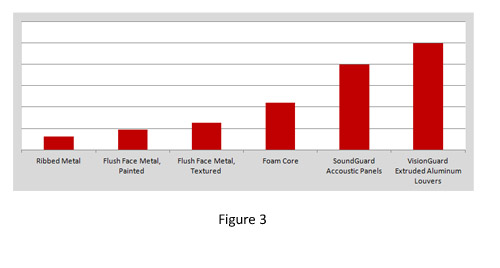

• Type of face panels: The type of face panels to be used on the roof screen can affect the price substantially. Panel materials and types vary greatly and have a huge price disparity. Ideally you should go to our Equipment Screen Cladding page and pick a panel so we can factor that in. But if you just don’t know yet, at least let us know the basic type of panel you are interested in. See Figure 3 for a basic idea of cost for different panel categories.

• Panel orientation: This is referring to whether you would like the panels to be mounted vertically or horizontally. In terms of cost, horizontal panels are generally less expensive because we can eliminate the horizontal girts required to support vertical oriented panels. However, most panels can’t span very far horizontally, so in a case where the frames are far apart, it may be more economical to go with vertical panels. We don’t expect you to know how to figure that out. What we really need you to do is tell us whether the panels absolutely have to be one way or the other, or if we can make that decision for you based on how the pricing works out.

• Roofing type: This one is not a real big deal, but can have some impact on pricing. If you plan on having us include roof flashing boots in the quote we will need to know what type of roofing system is being used. We offer TPO, PVC, all galvanized, and galvanized with lead base flashings. If you don’t need us to supply the flashings (perhaps the roofer is supplying them) then you can ignore this question.

• Thickness of rooftop insulation: RoofScreen base supports need to attach directly to the structural decking, so rooftop insulation plays a big role in determining the correct combination of base support heights and, if required, base extensions to achieve the proper height above the insulation. The taller the base supports, the weaker the frames become. When frames are weak, they must be installed closer together, which drives costs up. To accurately quote the roof screen, we need to know how thick the insulation is. If the insulation is tapered, you should provide us with the thickest point where a roof screen base attachment will be located. Sometimes this information is difficult to get. Ideally a core sample should be taken in various locations on the roof to get the most accurate thicknesses. We understand that may not be possible. So if no plans are available and you can’t take core samples, you’re stuck with guessing. We don’t want to guess for you (for obvious reasons) so just give us your best estimate and be prepared for the fact that if it ends up thicker, it could impact the pricing.

• Type of roof framing: RoofScreen bases must connect to something structural. For this reason, we need as much information as possible about the roof structure. The way we attach to the structure and even the type of frame we use may be affected by the type of roof structure. Below is a list of the most common types we see. Please try to get inside the structure to adequately identify the type. Pictures are always very helpful, so feel free to send them to us.

-

- Plywood decking over wood beams (4x width or greater)

- Plywood decking over 2x joists

- Plywood decking over 2x wood trusses

- Plywood decking over TJI joists

- Plywood decking over open web steel joists with wood nailer top chords

- Metal decking over open web steel joists

- Metal decking over steel I-beams

- Composite (structural concrete over metal decking) supported on open web joists or I-beams

- Structural concrete reinforced slab

- Insulating concrete over metal decking

• Structural member spacing: Once the type of structure is identified, we need to know how far apart the members are spaced. This is because the most economical way to build an equipment screen is to mount directly to the roof framing. This avoids the expense of adding support blocking. The spacing of the structural members in this case dictates the spacing of the roof screen frames, which is a big factor in the overall pricing. If the system is concrete, or you intend to add blocking regardless, you don’t need to worry about this question.

So as you can see, there’s a lot that goes into pricing a roof screen. The fact that you read this article show us you’re serious about it. We are too, and we want to help you as much as possible. We tend to work in a very collaborative way, so give us a call and let’s work through the details together. If you don’t have all the information we’re looking for, don’t worry about it. We’ll still put together the most accurate quote we can from the information you give us.

Let’s get started! Click here to Contact Us.