Aluminum Louvers

VisionGuard® Angled Louver

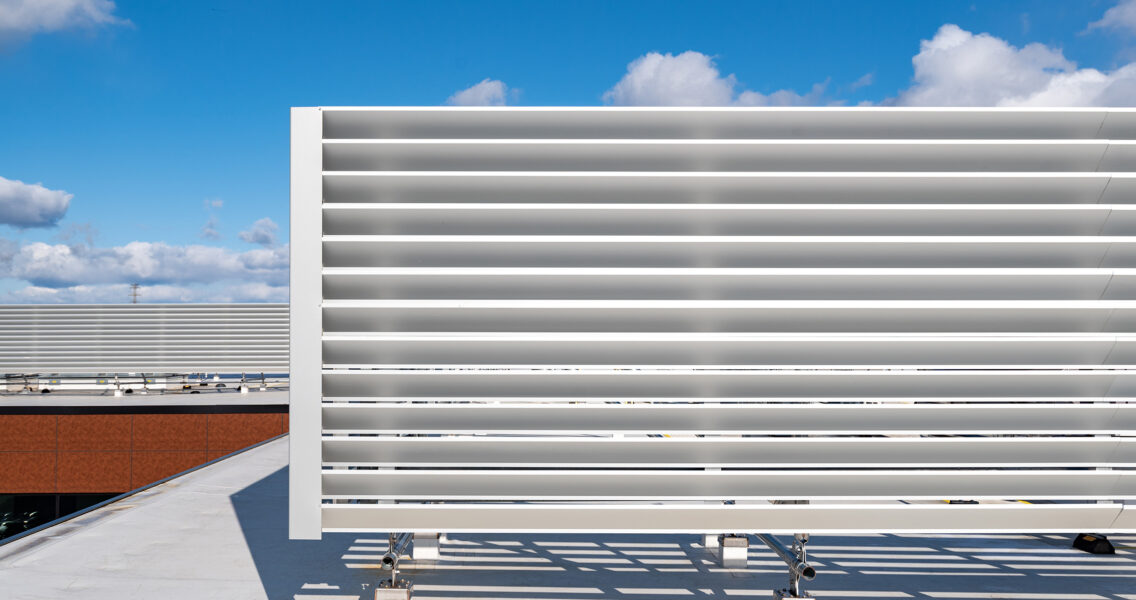

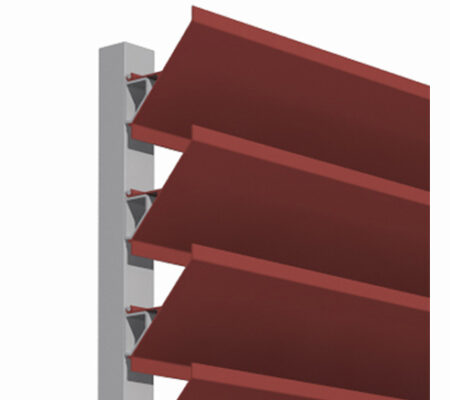

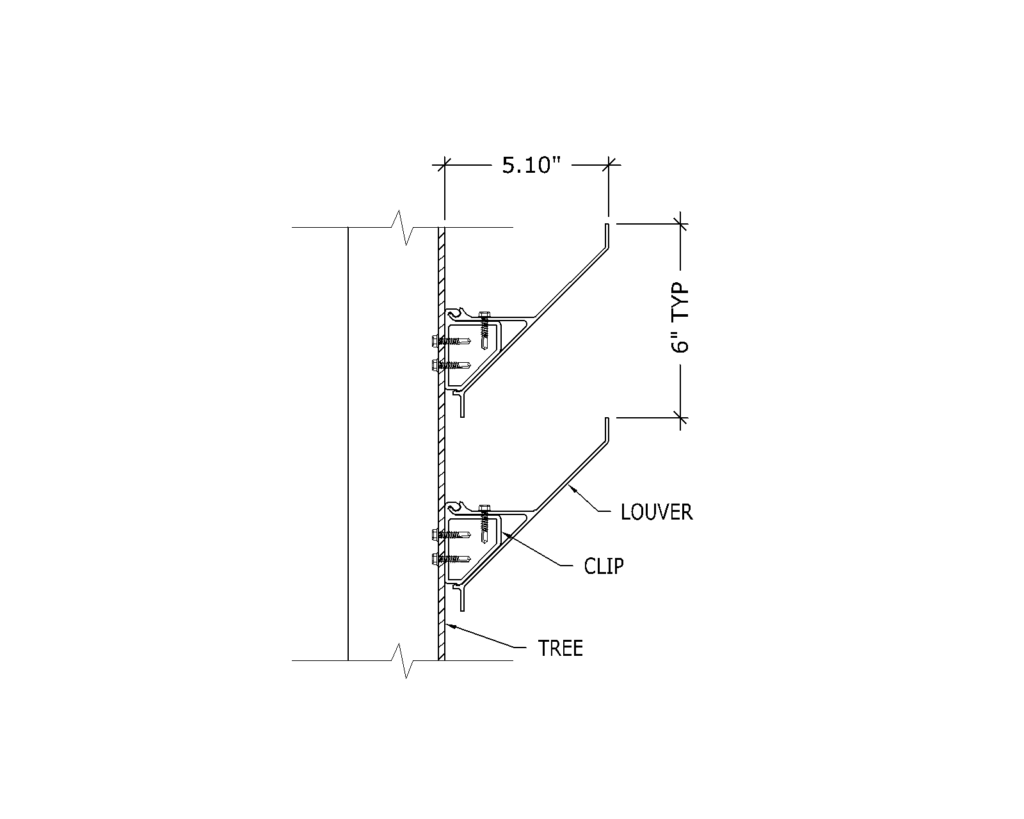

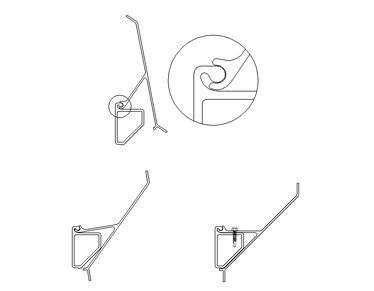

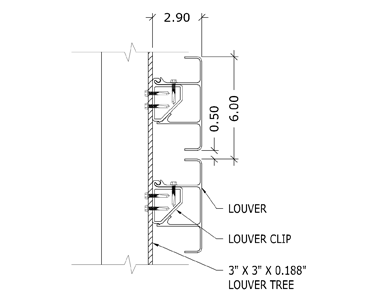

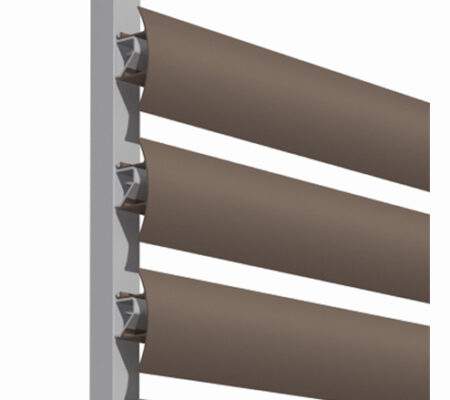

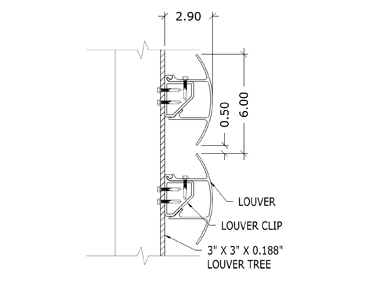

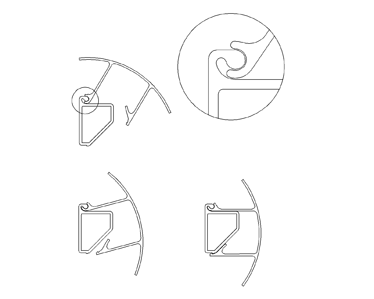

L10VisionGuard® Angled Louvers are inverted 45° straight blade louvers designed for architectural and vision proofing applications where a traditional angled louver aesthetic is desired. The continuous blade design with concealed snap-in retainer clips eliminates the need for unsightly vertical mullions or frame flanges.

When assembled, the inverted angle of the L10 Louver System provides a visual barrier from horizontal view. The standard blade spacing is 6″ but can be customized to any desired spacing. This louver system is ideal for use on a mechanical screen to block the view of HVAC equipment.

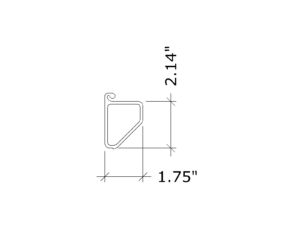

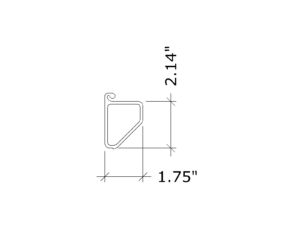

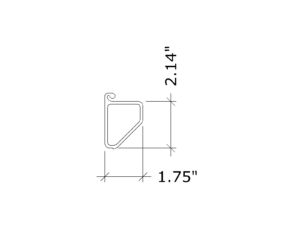

The extruded aluminum louver clip provides a concealed mounting point for VisionGuard® louver blades. The 3″ wide clip can be mounted to any flat surface. The distance between clips controls the blade spacing of the louvers and can be adjusted as desired.

Installing the L10 Louver System is simple. Rotate the louver arm into the clip and snap into place. To ensure the louvers stay in place under wind load conditions, install one tek screw through the top arm into the clip.

Material: 6063-T6 extruded aluminum

Lengths up to 24′

Attaches with concealed snap-in clips

Spans up to 12′ O.C.

Variable louver blade spacing available

Finish: paint finish meeting AAMA 2605, faux wood grain, anodized or mill finish

Warranty: 20 years

VisionGuard® Slatted Louver

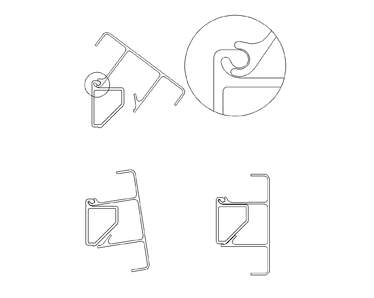

L20For projects where a slatted or lattice style effect is desired, the VisionGuard® Slatted Louver System is ideal. The blades are 5.5″ wide and the gap between blades can be specified to any distance desired. As with all VisionGuard® Louvers, the blades are continuous, eliminating frame flanges and vertical mullions common in other brands.

When assembled, the slatted rows of the L20 Louver System provide a visual barrier with as much, or as little free open area desired. The standard blade spacing is 6″ which leaves a 1/2″ gap between blades, but the gap can be customized to any desired spacing. This louver system is ideal for use on equipment screen walls for commercial rooftop applications.

The extruded aluminum louver clip provides a concealed mounting point for VisionGuard® louver blades. The 3″ wide clip can be mounted to any flat surface. The distance between clips controls the blade spacing of the louvers and can be adjusted as desired.

Installing the L20 Louver System is simple. Rotate the louver arm into the clip and snap into place. To ensure the louvers stay in place under wind load conditions, install one tek screw through the top arm into the clip.

Material: 6063-T6 extruded aluminum

Lengths up to 24′

Attaches with concealed snap-in clips

Spans up to 12′ O.C.

Variable louver blade spacing available

Finish: paint finish meeting AAMA 2605, faux wood grain, anodized or mill finish

Warranty: 20 years

VisionGuard® Curved Louver

L30VisionGuard® Curved Louvers are similar to the Slatted version but the face of each blade is curved to provide a more decorative style. Spacing between blades can be adjusted to any distance desired to allow more, or less view through the blades. The continous blades without vertical mullions or frame flanges provide a very streamlined visual effect.

The curved face of the L30 Louvers provides a unique aesthetic appearance while creating a visual barrier as well. The spacing between blades can be adjusted to achieve complete visual screening or leave as much opening as desired. This system works well as an equipment screen and can help enhance the aesthetics of any building.

The extruded aluminum louver clip provides a concealed mounting point for VisionGuard® louver blades. The 3″ wide clip can be mounted to any flat surface. The distance between clips controls the blade spacing of the louvers and can be adjusted as desired.

Installing the L30 Louver System is simple. Rotate the louver arm into the clip and snap into place. To ensure the louvers stay in place under wind load conditions, install one tek screw through the top arm into the clip.

Material: 6063-T6 extruded aluminum

Lengths up to 24′

Attaches with concealed snap-in clips

Spans up to 12′ O.C.

Variable louver blade spacing available

Finish: paint finish meeting AAMA 2605, faux wood grain, anodized or mill finish

Warranty: 20 years