Imagine putting ski racks on your vehicle and just screwing them down into the metal car roof. You would never dream of it. But that’s basically what roofers and contractors do every day on the roofs of commercial buildings.

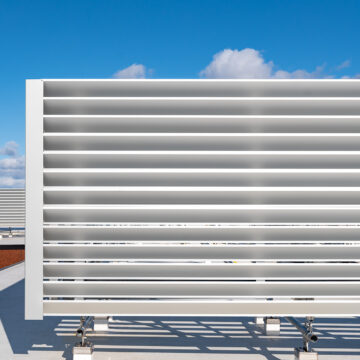

Wood and metal sleepers (or curbs) are commonly used to support all kinds of equipment on commercial rooftops. In a typical scenario, the sheet metal contractor installs a nice (and perfectly watertight) sheet metal sleeper cap and goes home. He’s done. The problem comes later when some other contractor mounts equipment to the sleeper. Whether it is an air conditioner, exhaust fan, compressor, gas pipe or some other type of rooftop equipment, the problem is the same. There’s no way to secure it to the sleeper without drilling a hole and screwing it down. A conscientious installer will at least use some caulking, but that’s only a temporary fix. It’s going to eventually leak, causing water damage, dry rot, mold and other problems.

The DryCap system solves that problem by allowing any type of equipment to be mounted to the top of the sleeper without penetrating the watertight barrier at the top surface. Internal cleats hold the DryCap to the sleeper, and the integral channels built in to the top of the cap allow equipment to be easily fastened and secured.

Learn more and watch our informative video by visiting our DryCap® Sleeper Cap System page.